Language:

Our HEA (High Energy Absorption) panels are the most rigid products of our Mac.RO ™ mesh systems offering extreme strength at low tension. The stiffness of the meshes is more important than the tensile strength since it affects the deformation of the system when applying a load.

The panels are woven, in rectangular mesh with different openings, from a continuous length high resistance steel cable joined at each crossing point with a double wire knot, patented, HEA and at its ends by an aluminum sleeve pressed according to EN 13411-3. Unlike single knot cable nets, HEA panel construction provides exceptional stress / strain performance with the least possible deformation. HEA panels are used as fixed membranes where little deformation and high strength are required.

Due to the multiaxial performance of the panel, loads are effectively transferred to the slope anchors regardless of the anchor arrangement.

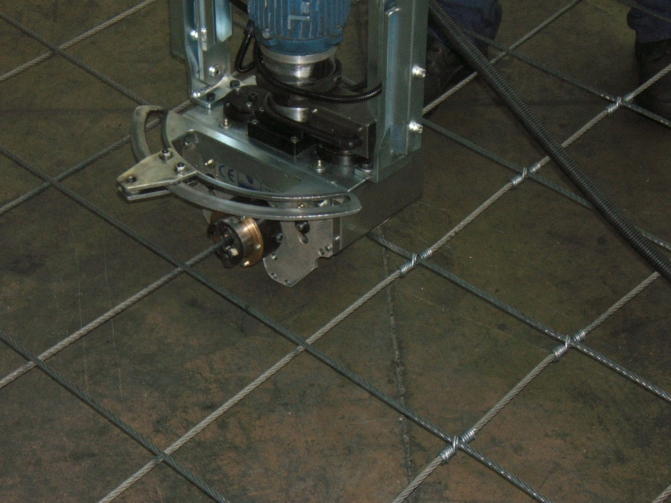

The patented joint knot is made with two links, each one is obtained by looping two steel wires with a diameter of 3.00 mm coated with Galmac® C3, an alloy of Zinc (90%) and Aluminum (10%) and rare earths. Both links will tightly wrap the wires crossing each other.

The panel is made with square meshes manufactured with a cable fixed by a pressed aluminum sleeve according to EN 13411-3.

Its tensile strength and punching are shown in the following tables (Performance that we guarantee through the CE mark):

|

Tensile Strength (UNI 11437) |

||

|

Mesh (mm) |

Srope Diameter Panel (mm) |

Tensile strength (kN/m) |

|

250×250 |

8 |

170 ± 17 |

|

300×300 |

8 |

160 ± 17 |

|

300×300 |

10 |

255 ± 15 |

|

400×400 |

8 |

125 ± 10 |

|

400×400 |

10 |

185 ± 15 |

|

Punching resistance (UNI 11437) (ISO 17746) |

|||

|

Mesh (mm) |

Srope Diameter Panel (mm) |

Final drilling load (kN) |

Final drilling displacement (mm) |

|

250×250 |

8 |

260 ± 15 |

240 ± 20 |

|

300×300 |

8 |

250 ± 15 |

280 ± 30 |

|

300×300 |

10 |

400 ± 25 |

310 ± 30 |

|

400×400 |

8 |

200 ± 15 |

260 ± 30 |

|

400×400 |

10 |

300 ± 20 |

310 ± 30 |

LEA (Low Energy Absorption) panels are a product made from a continuous length high-strength steel cable.

The junction at the crossover points is made using a patented double-piece clamp, LEA, which fixes the junction between cables, thus increasing the rigidity of the panel.

Our panels are the only ones on the market that guarantee their high performance in terms of resistance to traction, punching and duration of more than 200 hours in the salt spray test through Declaration of Performance (DoP) and the CE marking.

Performances are collected in the following tables:

|

Salt Spray aging Test (< 5% DBR) |

|||

|

Zn B |

Zn A |

Adv. Metallic Coating Clase B |

|

|

Minimum values according to ISO 17746 |

200 h |

500 h |

1000 h |

|

Values obtained in the test |

500 h |

1000 h |

3000 h |

|

Tensile Strength (ISO 17746) |

||

|

Mesh (mm) |

Tensile Strength (kN/m) |

Ellongation (mm) |

|

200×200 |

168 +/- 9 |

71 +/- 5 |

|

250×250 |

146 +/- 8 |

71 +/- 5 |

|

300×300 |

130 +/- 6 |

87 +/- 2 |

|

Punching Resistance (ISO 17746) |

|||

|

Mesh (mm) |

Final drilling load (kN) |

Final drilling displacement (mm) |

|

|

200×200 |

350 ± 18 |

390 ± 13 |

|

|

250×250 |

271 ± 14 |

369 ± 8 |

|

|

300×300 |

204 ± 5 |

328 ± 15 |

|

The Ring Net has the highest strength of the Mac.RO ™ family of meshes. With high strength performance, Ring nets are ideal for situations where there is a high risk of dynamic impacts. The nets are also used in conjunction with bolts to contain rocky slopes that characterize large rocky blocks prone to failure; Ring Nets can accommodate these high local stresses without high damage.

The technical performance of the Ring Nets was optimized to provide a balance of strength, weight and flexibility. The performance of the nets is dependent on the diameters of the wires, beam configurations and the number of points of contact with the adjacent rings within the panel.

Language: