|

GalMAC® Green wire (Class B Zn90- Al10) |

|

|

Diameter |

From 1,8mm to 5 mm |

|

Quantity of metallic coated |

Min 100 to 140 g/m2 (depending of the diameter) |

|

Breaking strength |

400-600 MPa (annealed) / 600 – 1000 MPa (hard) |

– GalMAC® Wires

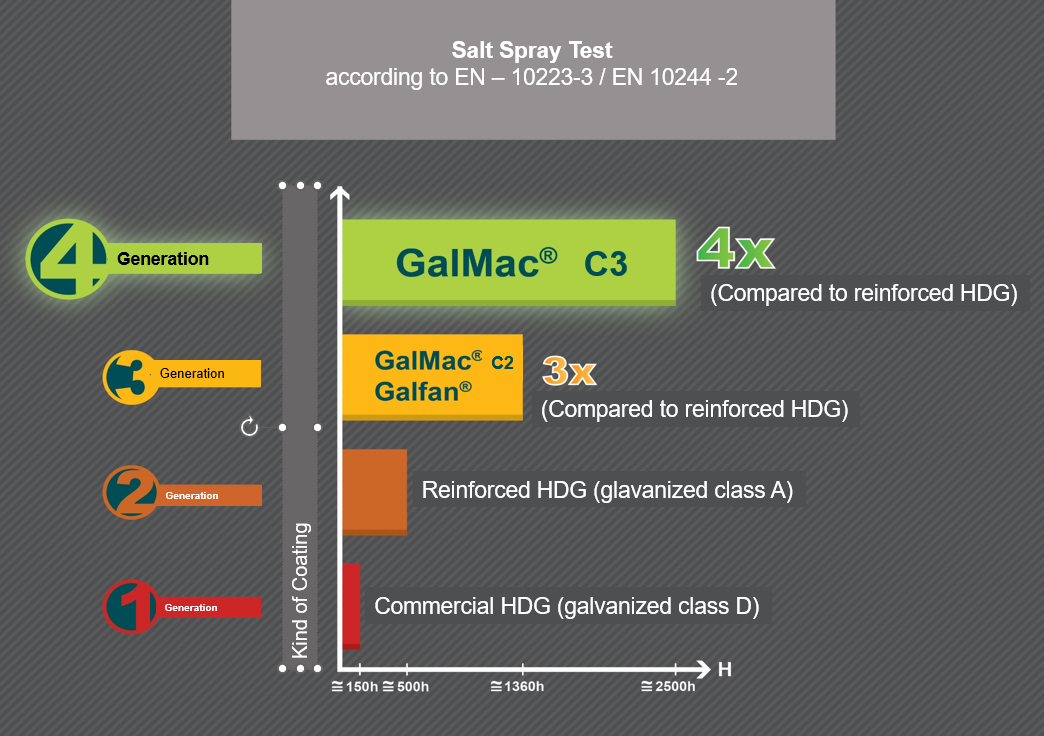

GalMAC® wire is a high purity zinc (Zn) alloy coated wire with 90% zinc, 10% aluminum (Al) and added lanthanum (La) and cerium (Ce). The corrosion resistance provided by this alloy is much higher than that obtained with traditional reinforced zinc coated steel or Galfan® alloy. Bianchini proposes 3 types of grades for this metallic coating: GalMAC® Green (class B), GalMAC® C3 (class A), and SuperGalMAC® (reinforced).

|

GalMAC® Green wire (Class B Zn90- Al10) |

|

|

Diameter |

From 1,8mm to 5 mm |

|

Quantity of metallic coated |

Min 100 to 140 g/m2 (depending of the diameter) |

|

Breaking strength |

400-600 MPa (annealed) / 600 – 1000 MPa (hard) |

GalMAC® Green wire is part of the new generation of wires generally used in enclosures (simple twist net, knotting, agriculture, greenhouses, and vineyards. GalMac® Green obtains better performance than a Galfan® class A wire, it resists corrosion 3 times more than a Galvanized (class A) and up to 10 times more than a commercial Galvanized.

GalMAC® C3 and SuperGalMAC® wire are products reserved for aggressive atmospheric environments (acid rain, industrial and urban pollution), and for Geotechnical solutions. GalMAC® C3 is the evolution of metallic coatings providing greater resistance to corrosion, increasing the life of products, such as gabions, Reno® mattresses, Terramesh®, double torsion nets, Steelgrid® for protection of slopes, or others, such as the Gaviarq®, electrowelded gabions also commonly used in architecture and landscaping.

|

GalMAC® C3 wire (Class A Zn90- Al10 ) |

|

|

From 1,8 mm to 5 mm |

|

|

Min 205 to 280 g/m2 (depending of the diameter) Min 350 g/m2 in Super Galmac® |

|

|

380-550 MPa (annealed) / 600 – 1000 MPa (hard) |

|

Galmac® C3: Better in performance with regard to corrosion than Galfan® class A, than a triple reinforced galvanized or a post-dip galvanized.

|

ADVANTAGES of GalMAC ® WIRE® |

|

– Low porosity – Less penetration of oxidizing agents – The high ductility and adhesion of the alloy to the wire allows it to work without cracking the coating. |